In modern packaging operations, efficiency and reliability are critical. The semi-automatic L sealer machine has become a staple in many industries due to its ability to provide consistent, high-quality seals while streamlining production. Businesses looking to improve their packaging processes often rely on these machines to save time, reduce material waste, and maintain product integrity. Whether for food products, electronics, or other consumer goods, L-sealer machines offer an effective solution for fast and precise packaging.

Overview Of The LMC Series L-Sealers

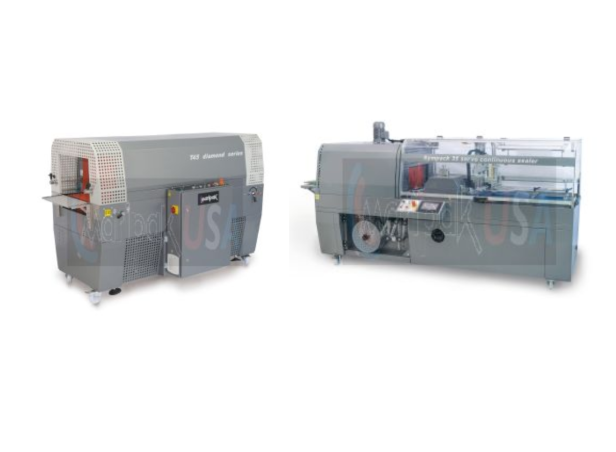

The LMC Series offers a range of L-sealer machines designed for different production needs. Two popular models, the 5844-M and the 8065-M, provide distinct features that cater to varying packaging volumes and operational requirements. Both models are designed to enhance productivity, ensure precise sealing, and integrate smoothly into packaging lines.

LMC 5844-M

The LMC 5844-M model is ideal for small to medium-sized operations. It features a user-friendly interface, adjustable sealing bars, and a compact footprint that fits easily into limited workspace areas. The machine is capable of handling various film types, making it versatile for different products. Its semi-automatic functionality allows operators to maintain control while benefiting from consistent, high-quality seals.

LMC 8065-M

The LMC 8065-M is a more robust option suited for larger production lines and higher-volume operations. It offers increased sealing speed, wider sealing capacity, and enhanced durability for continuous use. With improved automation features, this model reduces operator fatigue and increases throughput without compromising the quality of the seal.

Key Features Comparison

When comparing the LMC 5844-M and 8065-M, several features stand out:

- Sealing Width and Speed: The 8065-M provides a wider sealing area and faster cycle times, ideal for high-volume production.

- Film Compatibility: Both models accommodate multiple film types, but the 5844-M is particularly suited for lightweight films used in smaller packaging operations.

- User Control: The 5844-M emphasizes operator control with semi-automatic functionality, while the 8065-M incorporates advanced automation to increase efficiency.

- Durability: Both machines are built with industrial-grade materials, but the 8065-M is designed for heavy-duty, continuous operations.

Advantages Of Semi-Automatic L-Sealer Machines

The semi-automatic L sealer machine offers several advantages that make it a preferred choice for businesses of all sizes:

- Consistency: Provides uniform sealing across multiple products, reducing waste.

- Efficiency: Speeds up packaging compared to manual methods.

- Flexibility: Can handle a range of product sizes and film types.

- Ease of Use: Simple operation reduces training time for staff.

Integration With Shrink Wrap Packaging Machines

Many operations pair L-sealer machines with a shrink wrap packaging machine to create a complete packaging solution. After sealing, the shrink wrap machine tightly encases the product, providing tamper resistance, improved presentation, and added protection during transport. This combination is particularly valuable for businesses that ship products frequently or require high-quality packaging for retail display.

Maintenance And Longevity

Proper maintenance is key to getting the most out of any semi-automatic L sealer machine. Regular cleaning of the sealing bars, checking for wear on moving parts, and timely replacement of consumables ensure consistent performance and extend the life of the equipment. Investing in quality machines from trusted providers guarantees durability and reliability for years of service.

Conclusion

Both the LMC 5844-M and 8065-M L-sealer machines provide reliable solutions for modern packaging operations. The choice between them depends on production volume, workspace, and the level of automation required. Pairing a semi-automatic L sealer machine with a shrink wrap packaging machine offers a complete, efficient, and professional packaging solution. By understanding the unique capabilities of each model, businesses can make an informed decision that maximizes productivity, reduces waste, and ensures consistently high-quality packaging.