In today’s fast-paced industries, packaging plays a critical role in ensuring that products are safe, presentable, and ready for shipment. At the core of every packaging line is the machinery that makes this process efficient and consistent. Understanding the essential parts of a machine used in packaging systems helps businesses identify potential issues early and optimize their operations. From conveyors to sealers, each part contributes to the smooth running of the entire process.

Conveyors – The Backbone of Packaging Lines

Conveyors are often considered the backbone of packaging systems. They move products from one stage of the process to another, ensuring a steady and efficient flow. Whether transporting small items for sealing or heavy boxes for labeling, conveyors eliminate the need for manual lifting, reducing labor costs and workplace strain. When conveyor belts wear down or motors begin to fail, production slows dramatically, making them one of the most important parts of a machine to monitor regularly.

Wrapping Units for Product Protection

Another critical component of packaging systems is the wrapping unit. These sections of the machine apply stretch film, shrink wrap, or protective coverings to products before shipping. Wrapping not only prevents items from damage during transport but also enhances product presentation. Many industries rely heavily on wrapping machines to maintain product integrity. For example, in distribution centers, a Highlight Industries pallet wrapper troubleshooting guide is often consulted to quickly identify and resolve common wrapping issues. Proper maintenance of wrapping parts ensures packaging remains secure and reliable.

Sealing and Heat Application Components

Sealing systems are designed to close packages securely, often using heat or adhesives. Heat sealers, in particular, are vital for food and pharmaceutical packaging where airtight seals preserve freshness and safety. When these parts fail, it can result in leaks, contamination, or wasted materials. Sealing jaws, heating elements, and pressure plates are some of the most common parts that require monitoring and replacement. Without a properly functioning sealer, even the best packaging lines cannot deliver quality results.

Labeling Units for Traceability

Labels carry critical information such as batch numbers, expiration dates, and barcodes. Labeling units in packaging machines are designed to apply these identifiers quickly and precisely. Key parts of a labeling machine include rollers, applicator heads, and sensors. If these parts malfunction, mislabeling or missing labels can occur, leading to compliance issues and potential recalls. Proper calibration and timely replacement of these components help companies maintain accuracy and reliability in packaging operations.

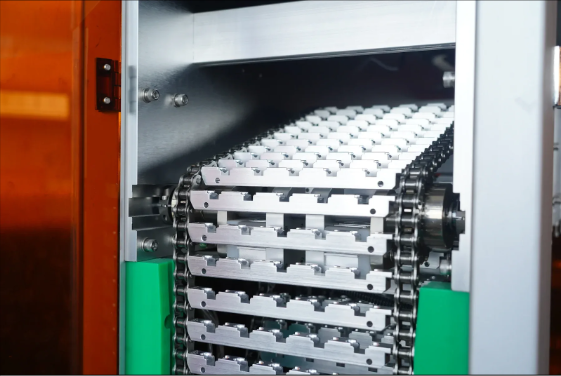

Cutting and Trimming Mechanisms

For packaging materials like shrink films, cartons, and laminates, cutting and trimming mechanisms are essential. These machine parts ensure materials are cut to the right size, reducing waste and keeping the process efficient. Blades, cutters, and trimmers dull over time, leading to uneven cuts or damaged packaging materials. Regular sharpening or replacement of these parts ensures a clean finish that enhances both efficiency and appearance.

Sensors and Control Panels

Modern packaging machines rely heavily on automation. Sensors and control panels are the brain of the system, monitoring everything from product flow to temperature levels. Sensors detect positioning errors, while control panels allow operators to adjust machine settings for precision. If sensors malfunction, misalignment, or product jams may occur. Control panel errors can lead to incorrect adjustments, affecting the entire line. These parts require careful inspection and calibration to ensure packaging machines operate at peak performance.

Feeding and Dispensing Components

In automated systems, feeders and dispensers handle the placement of items into packaging materials. Whether it’s food products being portioned into trays or pharmaceuticals being dropped into blister packs, these parts of a machine ensure accuracy and speed. Malfunctioning feeders can cause overfills, underfills, or product spillage, resulting in waste and inefficiency. Keeping these components in good condition ensures consistent product handling.

Maintenance and Troubleshooting of Machine Parts

Regular maintenance is key to extending the life of packaging machines. Companies that perform scheduled inspections and timely part replacements experience fewer breakdowns and lower operating costs. Troubleshooting guides provided by manufacturers are invaluable for diagnosing issues quickly. For example, many operators working with pallet wrapping equipment refer to Highlight Industries’ pallet wrapper troubleshooting manuals to address problems like film tearing or inconsistent wrapping tension. Being proactive with maintenance not only reduces downtime but also boosts overall efficiency.

Conclusion

Every packaging system is only as strong as its weakest component. From conveyors and wrapping units to sealing jaws and control panels, the essential parts of a machine must work together to deliver reliable results. Keeping these parts in good condition prevents costly interruptions, ensures product safety, and enhances brand reputation. Businesses that stay proactive with maintenance, inspections, and troubleshooting are better positioned to keep their packaging lines running smoothly and efficiently.